Carbon footprint

Reducing the carbon footprint is an important part of combating global warming. We are aware that, as a company, we contribute to the high emissions of the construction industry. But it is the way this is handled and what actions are taken that set us apart from the rest. At Aliplast, we take numerous actions to reduce our emissions and use energy as efficiently as possible.

Carbon control

A company's carbon emissions are the measure of how much carbon dioxide is emitted, while low carbon refers to its strategy on reducing these emissions.

Aliplast is part of the Corialis Group, which provides pan-European coverage to more than 60 countries through its decentralised hub structure with nine hubs around the world, ensuring efficient operations and customer proximity. The Corialis Group is continuously committed to sustainability and innovation.

Challenges posed by climate change

Climate change poses numerous risks that can threaten both nature and a company's financial health. Along with the environmental impact, there may also be financial hazards.

Financial losses from physical hazards of climate change:

- Operational risk: Heavy rainfall can lead to flooding, which can cause damage to facilities within the plant. In addition, extreme heat can not only reduce the efficiency of workers, but also cause breakdowns in the operation of equipment and machinery.

- Risk of revenue disruption: Energy problems due to drought and changes in water sources can lead to production shutdowns and rising costs, directly impacting company revenues.

We also need to look forward. By reducing our carbon emissions, we help reduce global warming. As a company, we strive to act in an environmentally conscious manner in all areas and contribute as much as possible to an energy-neutral future.

Current status and future plans

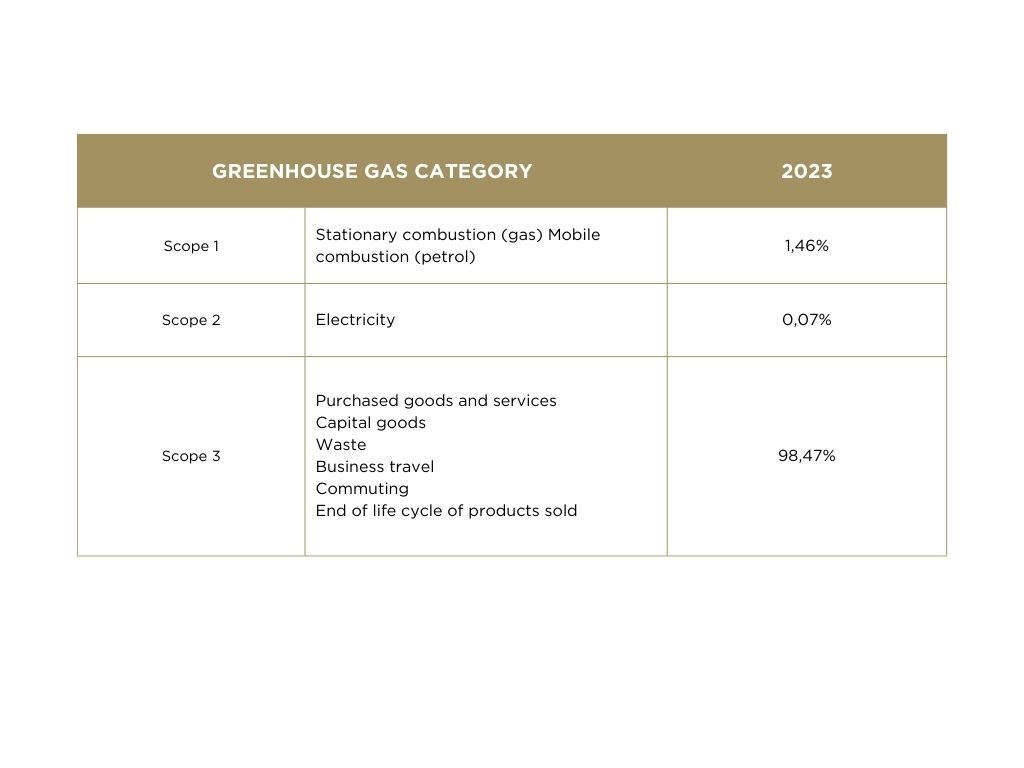

To be able to determine current emissions, we work in a subdivision of three scopes, which are generally defined. The three scopes are the following:

Scope 1: Direct emissions

Emissions from fuel consumption in our own vehicles or equipment or from industrial processes.

Scope 2: Indirect emissions from purchased energy

Emissions from the generation of purchased energy, such as electricity or heat.

Scope 3: Indirect emissions in the value chain

Emissions by suppliers, waste disposal, business travel, transport and customers' use and disposal of products.

Our scope 1 and 2 direct and indirect emissions represent only 1.5% of total emissions, with natural gas use accounting for the largest share. Scope 3 emissions, mostly from purchased goods (mainly billets), make up more than 98% of our footprint.

We work with suppliers on climate and emission reduction initiatives and collect specific carbon data to improve our scope 3 reporting and track our suppliers' progress. This enables us to reduce the biggest contributor to our emissions: the purchase of external aluminium billets.

Measures to reduce our footprint?

At Aliplast, we are working in various areas to reduce our footprint, with measures that address multiple aspects of our emissions.

- Sustainable production: Aliplast invests in energy-efficient production methods and optimises processes to increase production speed and reduce internal transport.

- Transport optimisation: Delivery routes to customers are planned in such a way that the minimum kilometres are driven.

- Recycling: We promote the use of recycled aluminium and ensure proper waste management.

- Green energy: The company uses renewable energy sources such as solar power to reduce its carbon footprint.

As a company, we are constantly looking for new ways to conserve energy and reduce our emissions. For each scope, we look at what improvements can be made:

Scope 1

We are setting up targeted studies to achieve further electrification within our production processes. We are also increasing the frequency of monitoring of refrigerant gas leaks.

Scope 2

We run our plants as efficiently as possible so that a minimum of energy is consumed. We aim to get as much the energy we use as possible from our own solar panels, supplemented by green certified electricity we purchase.

Scope 3

We want to increase the proportion of purchases we make from suppliers that conduct LCAs. Our goal is to encourage suppliers to participate in an LCA, because suppliers' specific emissions are often lower than the available average emission factors.

Green energy

At Aliplast, we are fully engaged in investing in green energy. For instance, we obtain renewable energy from 5,400 solar panels with a capacity of 1,600 MWh/year of green power, saving 664 tonnes of CO2 annually. These solar panels cover 20% of our total energy consumption. For the remaining energy needs, we purchase only certified green electricity, making our entire electricity consumption 100% green.

We take various measures to manage our gas and electricity consumption efficiently. For example, we switch off equipment when not in use and utilise residual heat from furnaces and compressors. Investment in modern infrared die furnaces has reduced our electricity consumption by 108,500 kWh per year.

To reduce the consumption of natural gas, Aliplast replaced the billet furnace, reducing our annual gas consumption by 296,000 kWh. The various actions taken to manage gas and electricity consumption as efficiently as possible will result in savings equal to the average annual consumption of 79 households.

We are striving to make our transport ever greener. There are currently 11 double charging stations and a double fast charger used by our employees and visitors. Moreover, they are publicly open to people from the neighbourhood from 8pm to 6am. We also aim to achieve a fully electrified internal fleet. We are also exploring opportunities with our external transport companies to get our products to customers in a sustainable way. For instance, starting in 2025, we will have an Xwift electric truck available.

In early 2021, our monitoring of our energy consumption and the various actions we take to minimise it was rewarded with ISO 50001 certification. This certification underscores our commitment to sustainability and innovation in our production processes.

SBTi

The Science Based Targets initiative (SBTi) is a climate action organisation that empowers companies and financial institutions worldwide to do their part to combat the climate crisis. They develop standards, tools and guidelines that enable companies to set targets for reducing greenhouse gas emissions to limit global warming to 1.5°C, in line with the Paris Climate Accords.

Corialis Group has confirmed its climate ambitions with the approval of the Science Based Targets initiative. Corialis commits itself to:

- Reduce the absolute scope 1, 2 and 3 greenhouse gas emissions by 25.5% by 2030 compared to reference year 2022.

- Increase the annual procurement of renewable energy for the entire group from 63% in 2022 to 100% in 2030. Aliplast itself already achieves 100%.

![[KEY1] [KEY2] [KEY3] [KEY4] [KEY5]](/uploads/nieuws/47/siteschuifraam1.jpg)

![[KEY1] [KEY2] [KEY3] [KEY4] [KEY5]](/uploads/nieuws/45/sitegevelbekleding.jpg)

![[KEY1] [KEY2] [KEY3] [KEY4] [KEY5]](/uploads/nieuws/49/siteduurzaamheid.jpg)

![[KEY1] [KEY2] [KEY3] [KEY4] [KEY5]](/uploads/nieuws/188/sitekleuren%201.jpg)

![[KEY1] [KEY2] [KEY3] [KEY4] [KEY5]](/uploads/nieuws/187/siteSomnium_R1_vb_web.jpg)